Depending on the part, there can be several challenges when printing parts. One is that the designs are not always completely accurate and may need to be fixed, or they used to be correct but are no longer compatible with my frame and skins and need to be personalized. All of that is before you even start the print!

After the print has begun, the first layer of the part must stick to the platform, or the entire print will be ruined. I have found one solution for this: painter's tape! Just place it flat on the bed of the printer (the part the print goes on) and make sure there are no, or almost no, gaps between the pieces of tape, and you're good to go!

Once you've picked a part to print and the printer is ready, you must check the amount of time it takes to print that part. Cosmetics can take anywhere from 6 minutes to 8 hours, so you must ensure that you will not be sleeping through the completion of the print. After a part has cooled, it is much harder to get off of the bed. The printer can also malfunction while printing and should be stopped immediately.

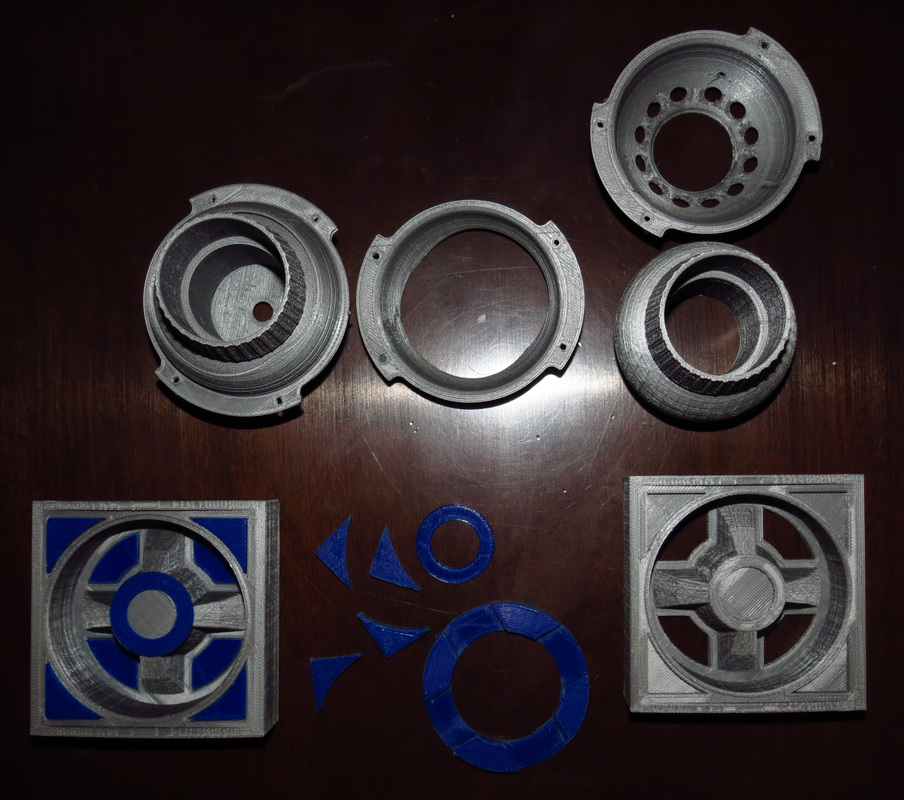

A few of the parts I am printing are the holo-projector eye, the decorative pieces on the arms, and the "coin slots". Each piece has a colorful name, but it's easier to list them according to their descriptions. I'll be loading a video of one or more of the parts as they print on my YouTube channel. Stay tuned!

RSS Feed

RSS Feed